Fluidized Bed Wurster Coater Sale Purchase

We are manufacturers of FBD Wurster Spray Coating Equipment Machine complete Machine in SS316. Complete machine with air filter, heat exchanger, product container, filter, blower, compressor Instrumentation & PLC and the working platform from plinth level is offered on turn-key basis. Our buyer's staff will be trained on our working machine. The offer will not be vague with many extras as every thing is be included.

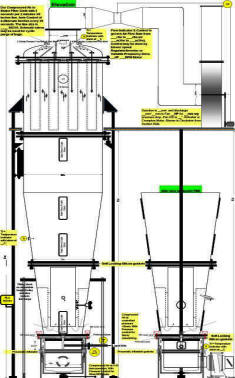

Click on the pictures to expand it and then zoom it.

Wurster spray coater is essentially a taller version of fluidized bed drier. Plant scale wurster machine is about 5meters (17 feet) tall and it needs about 6.5meters (22feet) clear space from the ground. A Wurster equipment can be easily used as a fluidised bed drier by removing the spray nozzle and the partition in the product container. The bottom plate needs only minor modification. It can be used as a top spray granulation and coating machine by retrofitting a top spray nozzle. You can have both the units i.e. top-spray and bottom-spray to begin with by just adding a top-spray nozzle to it.

The complete assembly consists of an Air handling unit followed by a Heat Exchanger. Filtered air is heated and it enters the wurster tower. The product particles are fluidized in the tower and coated by spraying an emulsion or any other coating liquid from the bottom. After fluidization, the exhaust air passes through a an expansion chamber and then a filter system. Air for fluidization is sucked by a blower which is attached to the top exit of the tower. A cyclone separator and/or scrubber may be required for better control of air pollution. Standard parts include a peristaltic pump for emulsion or liquid spraying, mixing tank for coating liquid, an Air compressor, a dry air unit for instruments and filter cleaning and instrumentation for automatic operation. Our offer also includes supporting structures and the platform. Safety flap is fitted at two places; one on the top dish and the other on the shell.

Offer for Plant Size Wurster Coating Machine. The product container volume will be 200 liters to 1000 liters.

Air Handling Unit: It consists of a filter followed by a

heater.

Filter: A pre-filter of 20 microns, followed by a final filter of

5 microns is used.

For a very strict air quality requirement, a HEPA filter

may be used. Use of finer filter will increase the blower load. This offer

is for 5 micron filter

Heater: Shell & Tube type heat

exchanger, fitted with continuous tension wound crimpled fin tubes is used.

Heating may done by steam or by thermic-fluid.

The MOC (Material of Construction) is SS316.

Main Tower: A plant size machine requires not less than 5

meters (17 feet) height. It consists of a jacking system followed by product

container fitted with a wurster spray nozzle, expansion chamber and filter

unit. The MOC (Material of Construction) is SS316.

Product Container: The product container is trolley mounted conical vessel with a

wire-mesh at the bottom placed on a specially perforated bottom plate. In the center of the product container, there is a coating

partition that has an arrangement to adjust the gap from the bottom. This

adjustment can be done from outside the container. A sight glass and light

glass are fitted at the bottom to observe the performance of fludization and

wurster action. A sampling port is provided. Two such containers are offered

with each machine to ensure minimum down town in loading and unloading a

batch.

Spray Nozzle: A specially designed

wurster spray nozzle enters the

bottom plate. The nozzle is easily removable and it gives a fine spray for

the most desirable coating.

Expansion chamber: Ample space is provided above the product

container for the fluidised material to remain suspended after the spray.

Filter: The reverse purging by compressed air

in cage filters is used. The cages are divided in to 4

parts and each part is cyclically shaken for 5 seconds, every 2 minutes.

Blower: Blower is generally kept on the mezzanine (or it may be placed

some distance away). We offer

body-casing and the fan made of SS316. The attached motor and bearing etc

are not available in SS316 and it may be fitted as per availability. The

blower will be ___ HP

Compressor: A compressor is needed for spraying and for the filter

purging. It is included in the offer.

Dry Air Unit: Provided for Air purging and instrumentation.

Mixing Tank: Emulsion storage & Mixing Tank for a batch size is

included.

Structure: Support structure, ladder and mezzanine is included. The

MOC (Material of Construction) is MS. The buyer may cover it with FRP or

with SS-sheet.

Peristaltic Pump: 1-1800 ml/minute in SS316 GMP model is included.

Instrumentation & Controls: The main instruments and controls consist

of:

1. Venturi Flow meter to measure the air flow rate and control it. A PLC

based Venturi meter is used for the same. A Variable Frequency Drive VFD is

used to control the speed of the motor to give a constant desired flow rate.

2. Compressed Air is used to Shake Filter Cloth with 5 seconds per 2

minutes. Auto Control of 4-Alternate Section every 30 seconds. Solenoid

valves may be used for cyclic purge of bags.

3. Temperature Indicator with alarm set at __C is used monitor temperature

of the inlet air and of the product container. Exit air temperature is also

measured. PLC can be set to shut-off the system against any parameter that

is sensitive.

4. Pressure indicators are used to measure the pressure of spray atomizing

air and of shut-off needle.

PLC Controls and eight days hands down training for two people of buyers company in our running plant is included.

Please check theory & logic wurster coating machine

The price of the machine is 200K USD FOB Mumbai, India for a -200 liters

product container machine in SS316

The price of the machine is 220K USD FOB Mumbai, India for a -400 liters

product container machine in SS316

The price of the machine is 240K USD FOB Mumbai, India for a -600 liters

product container machine in SS316

The price of the machine is 260K USD FOB Mumbai, India for a -800 liters

product container machine in SS316

The price of the machine is 280K USD FOB Mumbai, India for a 1000 liters

product container machine in SS316

Machines are also offered in the following ranges:

Laboratory Wurster Coater from 1 liter per batch to 10 liters per batch a

single machine with interchangeable product bowl is good enough in the

entire range.

Small Wurster Coater of 25 liters/batch, 50 liters/batch, 100 liters/batch a

single machine with interchangeable product bowl is good enough in the

entire range.

For calculating the batch size in kg use the formula: 90% of Volume in liters*Bulk Density of product. Select a size not more than 3 times the minimum batch size that you anticipate (Better still 2 times the minimum batch size that you anticipate).

Please send your enquiry to ajk@wurstercoating.com.

Wurster Coating Company

Ankleshwar Gujarat and Mumbai Maharashtra, India.

Every thing about Wurster Coating Process Parameters, Principle and Scale

up will be covered here.

We offer encapsulated chemicals.

1-may-22