Spray Nozzles for Wurster Coater

Several pages will not be sufficient to describe spray nozzles. However important aspects of Wurster Spray Nozzles will be described here.

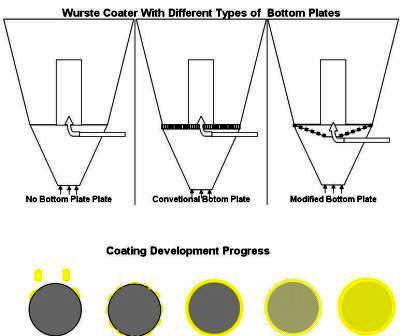

The nozzle is fitted at the bottom of the wurster and it projects into

the perforated bottom plate.

It must give a fine enough spray. The mist must not be too fine, where it

spray-dries before touching the particles to be coated. It must not give too

big droplets, that will act to stick two or more particles together.

Air-less one media nozzle must be avoided.

External mixing of atomizing air and spray emulsion is a desired spray

nozzle.

It must have an auto-shut-off needle to prevent clogging of the nozzle.

Atomizing air is generally used around one bar pressure.

Several OEM makers of Wurster Coaters, compromise on this aspect either due to prohibitive cost of the nozzle and/or due to lack of knowledge. The nozzle must be easily detachable.

We offer Wurster spray nozzles for laboratory size machine to plant size macines.

Please send your enquiry to ajk@wurstercoating.com.

Wurster Coating Company

Ankleshwar Gujarat and Mumbai Maharashtra, India.

Every thing about Wurster Coating Process Parameters, Principle and Scale

up will be covered here.

We offer encapsulated chemicals.

1-may-22